-

Call Us Now +86-576-81116176

-

Send Mail To info@aicmould.com

AIC mould into plastic inection moulding industry more then 10 years. We insist to choose suitable mould machining, use high quaility moluld spare part, strict to check every step. High quality mould, suitable price is our aim.

Our Advantage of:

1.Customized mould making according to customer's requirements

2.Experienced group for part&Mould design

3.On-time delivery

4.Advanced Equipment

5.One-year-warranty for each mold

plastic pallet mould

AIC mould is one of the pallet mould supplier in China.We supply nestable pallet mould, two-way pallet mould,stackable pallet mould, rackable pallet mould, close,open deck pallet mould and so on.

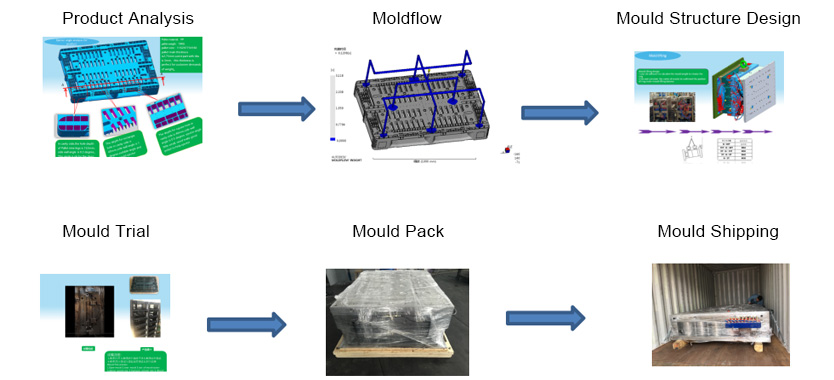

Steps of plastic pallet mould process:

1. 3D pallet design DFM report and mold-flow analysis.

When we got 3D model of plastic pallet from customer.We will Organize various relevant departments to hold meetings.The main purpose of the conference is to analyze the project of the pallet products. The pallet mold flow analysis is indispensable. It can intuitively show us the influence of the position of the runner gate arrangement on the injection molding of the pallet product. And through the pallet mold flow analysis.,to further verify the mold requirements for the injection molding machine.Meanwhile, our technical department will give DFM report according their pallet mould experience. De-molding angle, strength, pallet filling,thickness, deformation, sink mark, all this will be show on the DFM report. If there are any points that do not match for the pallet mould, we will communicate and modify with customers at any time.

2.Pallet mould design

After discuss and modification for the pallet products, it was totally match with the mould construction. The next step work is plastic pallet mould design. Mould design is the base for one projects, the successful projects must be with good pallet mould design. The basic structure of the pallet mold, the steel material, the MFI for pallet material, the special requirements of the customer, and the technical standards of the AIC mould will be re-emphasized at the meeting. At the same time, each department clearly defines its own tasks and responsibilities, and provides customers with the best pallet mold solutions.

3. Mould process for pallet mould

When we got approve of pallet mould design from customer, the projects are start.The arrangement and selection of machine steps is very important in the pallet mold manufacturing process. Machine selection determines the success or failure of the pallet mold details, and the machine arrangement affects the T1 time. We have a professional team that can make reasonable arrangements for the mold processing steps and choices. The delivery of project progress reports every week is critical to the customer's understanding of pallet mold progress.

4.Adjustment for pallet mould

small modification will done after T1. Before pallet mould left factory, all the point will be carefully check by mould maker.

AIC mould welcome you to visit our factory and discuss your mould projects with us.

Please leave your Email or phone nomber, so we can contact you as soon as possible.