-

Call Us Now +86-576-81116176

-

Send Mail To info@aicmould.com

AIC mould is plastic injection mould manufacturer from mould town of China.We specialized in making different type of pallet molds, crate moulds,bulk container moulds,chair molds, bin moulds, stool moulds, storage container moulds, commodity moulds and so on.

Our Advantage of:

1.Customized mould making according to customer's requirements

2.Experienced group for part&Mould design

3.On-time delivery

4.Advanced Equipment

5.One-year-warranty for each mold

AIC mould is a company which could supply solution for different type of moulds like pallet moulds, crate moulds,pail moulds, dustbin moulds, helmet moulds, bin moulds,commodity moulds, spool moulds and bobbin moulds. We have been in this injection mould industry for more than ten years and have a experienced production and R & D team. 90% of the injection molds of our company are exported to aboard countries. Injection moulds is a customized products. According to different needs of customers,Our mould quality and service have been recognized by many customers.

Detail information of mould:

Name:plastic bobbin and spool mould

Mould base: Home made mould base

Mould Steel: P20

Ejector system: hydraulic cylinder

Runner system: cold runner

plastic material of bobbin: PP

cavities: 2 cavity

Bobbin mould design software: UG,Auto CAD

packing :Wooden box

Bobbin mould T1 time:35 days

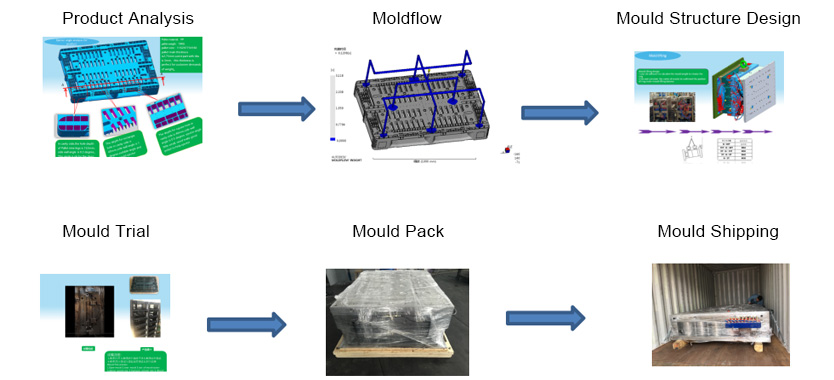

About the process of bobbin mold customization:

Quotation:How to get quotation,customer supply 3D drawing or 2 D drawings, or samples. And give the details demands for mould, like how many cavity prefer to make, how many Tons of injection mould planning to use, Which brand of hot runner are in your list.

Consultation and discussion: Discuss about the bobbin mould solution depends on the cost we gave. If have different idea, need adjust the mould solution and mould cost.

Order mould and pay advance payment: We will start mould projects once we get advance payment.

Part design and mould design: Before make bobbin mould design, we need confirmed the product design first. Some times, product design is very good, but it might be not suitable for mould construction. Only by laying the foundation well,the entire project will smooth.

Mould making process:After confirmed bobbin mould design, we will start mould manufacturing.Each step of spoon mold making will be discussed, and mould machining processing will choose the best to meets the product characteristics. At this time, mould maker and machining people played a key role. The mutual cooperation between them can ensure the quality and delivery time of injection spool molds.

T1: bobbin mould trial video, machine parameter,cooling water will connect,material specifications, all this information will supply

Mould Delivery:cooling system, new pipe fitting, mould side lock and all the spare parts will change to demands.Double protection of anti-rust agent and lubricating oil, the film is wrapped up, and then put into a strong wooden box

Advanced mould production equipment and professional technical mould manufacturing team have jointly created AIC mould with excellent steel materials, high precision, short delivery time, and great after-sales service. We sincerely hope to work hand in hand with new and old friends from all over the world.Welcome to contact us.

Please leave your Email or phone nomber, so we can contact you as soon as possible.